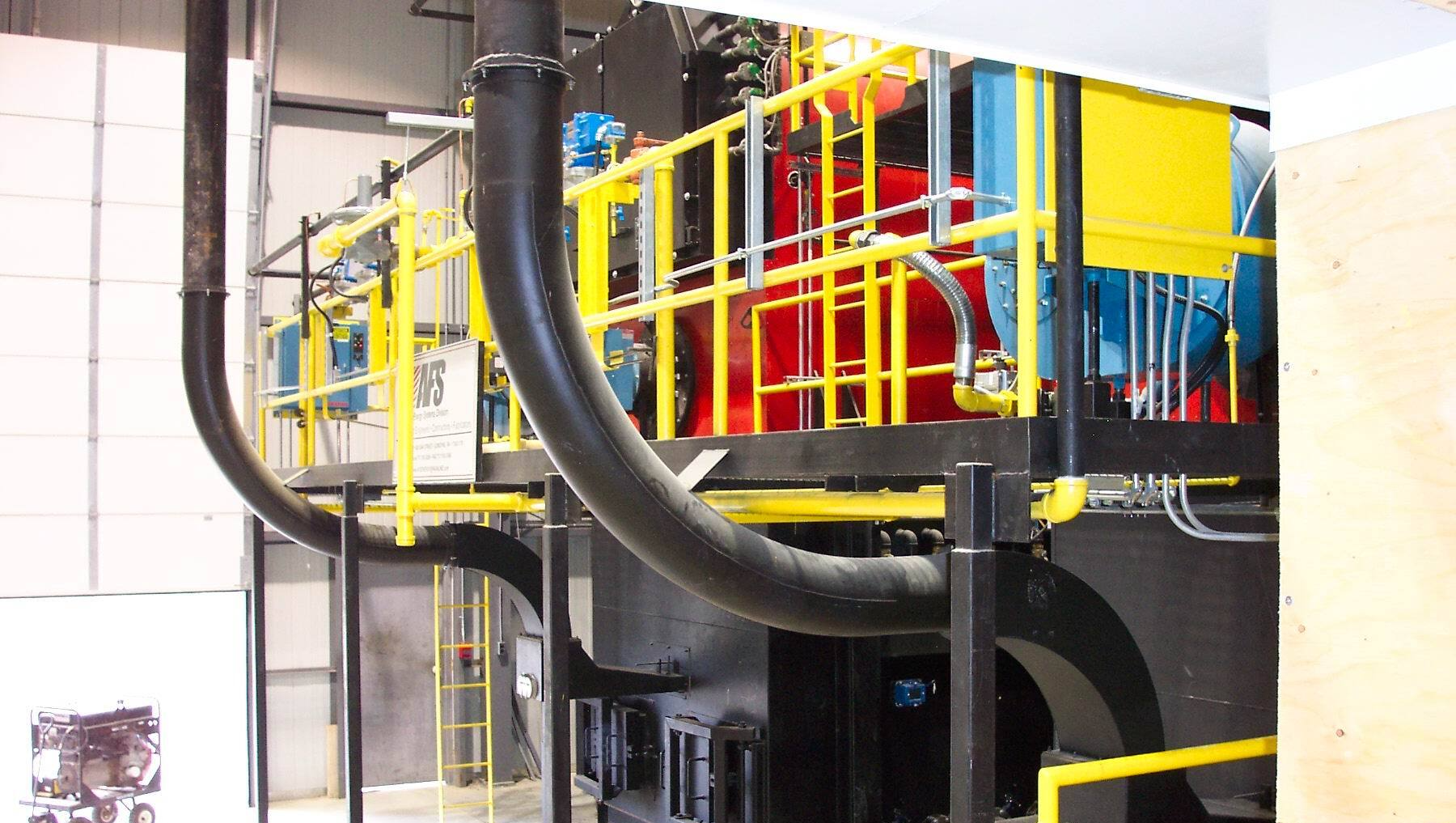

THE LEADER IN RENEWABLE ENERGY BIOMASS SYSTEMS

Phone 717-763-0286

Biomass Energy

Steam, Hot Water, and Air Systems

Biomass Energy Solutions use biofuels that provide clean, sustainable, and renewable energy for organizations. Organizations looking for sustainable development are using biomass energy systems to increase energy output, reduce emissions and decreasing energy costs. AFS is committed to creating a custom strategy using biomass & renewable energy technologies to meet your individual energy needs.

AFS Energy has designed, fabricated, and installed over 125 biomass energy systems in the US & Canada. In all, these systems are burning over 1,500,000 tons of renewable fuel yearly which produces over 50,000 bhp & 1,828,600,000 btu/hr. Biomass can be such an efficient and reliable solution that our clients often experience a payback of 2 to 3 years on their systems.

AFS Energy Systems has been in renewable and sustainable energy industry since 1990. Between the 3 founding members you will have access to over 120 years of combined engineering experience in the Biomass industry.

Examples of biomass fuels are agricultural biomass, sawdust, wood, bark, pellets, oat hulls, rice husk, chicken manure, nuts, shells, husks, paper, & card/board products.

Your labor requirement should be reduced with an AFS biomass energy system as our systems require very minimal human intervention. The AFS Total Control System uses state-of-the art computer, Primary Logic Controller (P.L.C.) and Variable Frequency Drive (V.F.D.) technology and logic to automatically control your energy system.

If an issue arises, the system automatically contacts your Operator so constant oversight isn’t necessarily required. Bottom line – the average system administrator spends 2-4 hours per week caring for the biomass system!

High Pressure Steam Systems

Water Tube / Fire Tube Boiler

100 to 1,200 Boiler Horsepower

150, 300 & 450 psig

Water Tube Boiler Steam Systems

10,000 #/hr. to 60,000 #/hr.

300 to 900 psig

Low Pressure Steam Systems

Firebox Boiler

35 to 600 Boiler Horsepower

15 psig

Hot Water Boilers

35 to 600 Boiler Horsepower per Boiler

30 or 60 psig

Organic Rankin Cycle (ORC)

Combined Heat & Power (CHP)

Output 300 KW to 2.4 MW

176 Deg. F to 248 Deg. F, Hot Water Temp.

Hot Air Systems

1 Million to 20 Million BTU’s/hr.

Automatic Ash Removal Furnace

Pneumatic Injector Stoker System

Overfed Stoker System

Video: EMD Biomass Boiler with material handling,

screening, storage and material transfer.

Video: 600 hp Biomass Fired Boiler System, Fuel Firing System modification to Hurst 600 hp Biomass Fired Boiler System, and 800 HP Biomass Fired Boiler System with automatic ash removal.